Why You Need To Pick Professional Commercial Refrigeration Repair in Toronto

Why You Need To Pick Professional Commercial Refrigeration Repair in Toronto

Blog Article

The Ultimate Overview to Commercial Refrigeration Fixing: Usual problems and vital actions Clarified

Usual Business Refrigeration Concerns

When running business refrigeration devices, organizations may run into several typical issues that can impact the effectiveness and functionality of the tools. Changing temperature levels within the refrigeration system can lead to food perishing, raised power consumption, and endangered high quality and safety requirements.

Another usual issue is refrigerant leaks. Leaks can arise from damage, poor installation, or producing defects. If left unaddressed., reduced cooling agent degrees not only prevent the system's cooling capability however can likewise lead to compressor failing.

In addition, ice buildup on evaporator coils is a regular problem. Ice accumulation restricts air flow, causing the system to function tougher and eat even more power. Routine cleaning and maintenance of the coils can help prevent this issue.

Vital Tools for Repairing Refrigeration Units

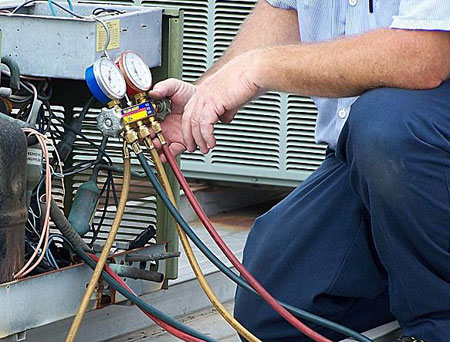

Making use of the suitable tools is essential for effectively fixing commercial refrigeration systems to guarantee optimum performance and longevity. Among the fundamental tools needed are manifold gauges for checking refrigerant pressures, refrigeration wrenches for tightening up or loosening fittings, a multimeter for testing electric parts, and leakage discovery tools such as digital leakage detectors or ultraviolet color kits.

In the world of specialized tools, tube cutters and flaring tools are important for dealing with copper tubes, while a healing device is required for securely getting rid of refrigerants. In addition, a temperature weapon can be beneficial for promptly recognizing temperature differentials within the device. Purchasing high-quality devices not just improves efficiency throughout repairs yet likewise adds to the precision and reliability of the upkeep job brought out on commercial refrigeration devices.

Step-by-Step Troubleshooting Guide

The next action is to examine the temperature level controls and settings to ensure they are functioning appropriately. This consists of inspecting the thermostat, defrost timer, and other control devices to validate that they are controling the temperature as intended. Adjustments or substitutes might be needed. if any type of discrepancies are located.

Consequently, the service technician must take a look at the condenser and evaporator coils for dirt or debris buildup, which can hinder proper cooling. Cleaning these parts can often settle concerns with temperature level regulation and efficiency.

Preventative Maintenance Methods

Carrying out regular preventative maintenance steps is vital for making certain the long life and optimum performance of industrial refrigeration systems. By adhering to a positive maintenance timetable, services can lessen the danger of costly malfunctions, avoid downtime, and extend the life-span of their refrigeration equipment.

One crucial preventative upkeep technique is routine cleaning of condenser coils. With time, these coils can collect dust, particles, and dirt, which can impede warm transfer and decrease the system's efficiency. By cleaning the coils occasionally, companies can make certain that the refrigeration system operates at peak efficiency.

Additionally, inspecting and changing worn gaskets on doors is one more crucial upkeep job. Damaged gaskets can cause air leakages, causing the refrigeration system to function review harder to preserve the wanted temperature. By replacing malfunctioning gaskets promptly, companies can boost power efficiency and extend the life of the tools.

Incorporating these preventative maintenance methods right into a comprehensive maintenance strategy can aid businesses enhance the efficiency and integrity of their commercial refrigeration systems.

Professional Repair Service Vs. DO IT YOURSELF: Disadvantages and pros

Involving a specialist fixing solution for business refrigeration systems supplies distinctive benefits over trying Do it yourself repair work. Commercial refrigeration systems are complicated systems that need specialized understanding and skills to diagnose and repair effectively.

Trying to repair a business refrigeration system yourself can lead to additional damages if not done correctly, possibly resulting in even more costly fixings down the line. While DIY repair services might seem economical initially, the long-lasting advantages of professional repair service solutions outweigh the dangers and unpredictabilities connected with trying repairs on your very own.

Conclusion

In final thought, comprehending usual commercial refrigeration issues, having the necessary devices for repair, complying with a detailed troubleshooting guide, and executing preventative upkeep strategies are key components of keeping and fixing Toronto commercial refrigerator repair commercial refrigeration systems. While specialist repair services might supply know-how and performance, do it yourself repairs can also be an economical alternative for those with the essential abilities and expertise. Inevitably, normal upkeep and timely fixings are essential for ensuring the proper functioning of commercial refrigeration units.

Recognizing the crucial actions for business refrigeration repair service and being able to recognize common issues are essential skills for any business proprietor or upkeep employees. In this detailed overview, we will certainly check out the essential steps and common concerns in business refrigeration repair service, furnishing you with the knowledge needed to resolve these difficulties efficiently.

Engaging a here specialist fixing service for commercial refrigeration systems supplies unique advantages over trying DIY repairs. Trying to repair a commercial refrigeration system yourself can lead to further damage if not done correctly, possibly resulting in even more expensive repairs down the line.In verdict, comprehending usual industrial refrigeration issues, having the vital tools for repair work, following a step-by-step troubleshooting guide, and executing preventative upkeep strategies are vital components of preserving and fixing industrial refrigeration units.

Report this page